Planetary Mixers

Home » Concrete Mixers » Planetary Mixers

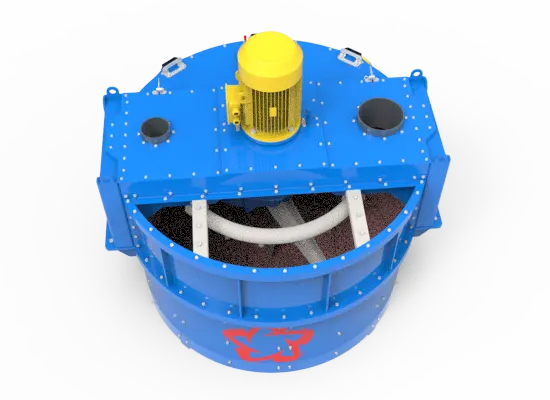

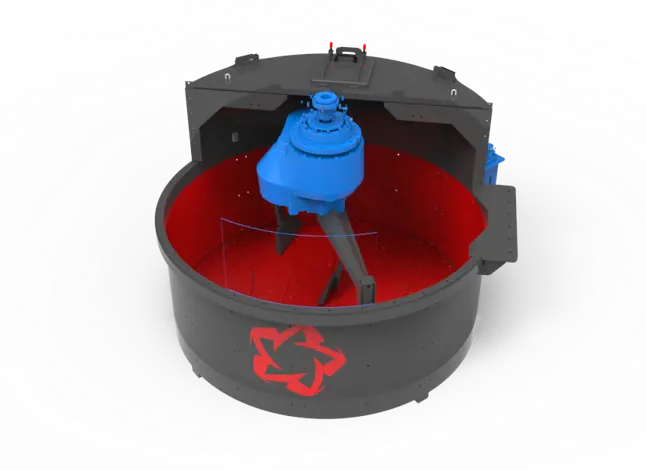

Planetary Concrete Mixer: High Homogeneity and Concrete Quality

High Homogeneity is indispensable for the quality of concrete. One of the most successful of different types of concrete mixers is planetary mixers. Our Planetary Mixer Model with Capacity Varying Between 0.5 m³ and 1 m³; It is the type of mixer whose drive is above the mixer. It is preferred according to the design and cost of the concrete plant. In addition to having high performance, it has a stylish and aesthetic appearance. It is easy to use and clean. It complies with CE standards.

HIGH LEVEL HOMOGENEOUS

Due to its working principle, the mixing quality is at the highest level in planetary concrete mixers. If the capacity of the project is sufficient, it is the concrete mixer most preferred by our customers.

HIGH QUALITY COMPONENTS

In our Planetary Concrete mixers; We use the equipment of global brands that have proven their quality. The spare parts of the equipment we use are easily available in the markets, so you can continue your production with minimum interruption and long-term reliable operation.

DURABLE AND LONG LASTING

The average life of the mixer group depends on the wear-free plates and the casting thickness of the mixer. Therefore, as Umman Concrete, we produce our mixers with extremely thick and wear-resistant plates.

LUBRICATION SYSTEM

One of the biggest advantages of planetary mixers is the ease of maintenance and the fact that they do not need a continuous lubrication system due to the fact that the shafts are at the top.

HIGH QUALITY

The manufacturing processes of all UMMAN products produced are in full compliance with ISO 9001, CE Legislation, OHSAS and EAC Standards and other specific quality and safety-related directives.

QUALITY CONTROL

As UMMAN, we aim to produce quality and error-free products by constantly monitoring and controlling our products by our quality control unit during the production phase.

Technical Specifications

| SPECIFICATION | UNIT | DEĞER |

|---|---|---|

| Mixer Capacity | m³/h | 0.5 |

| Dry Filling Volume | Litre | 750 |

| Compacted Concrete | Litre | 500 |

| Motor power | kW | 1×22 |

| Electric Delta Connection | 380V/50Hz | |

| Motor RPM | rpm | 1450 |

| Mixer Arms | Qty | 3 |

| Scraper Arms | Qty | 2 |

| Hydraulic System Motor Power | kW | 1.5 |

| Mixer Arm RPM | rpm | 24 – 63 |

| Weight | kg | 2500 |

| SPECIFICATION | UNIT | VALUE |

|---|---|---|

| Mixer Capacity | m³/h | 0.5 |

| Dry Filling Volume | Litre | 750 |

| Compacted Concrete | Litre | 500 |

| Motor Power | kW | 1×22 |

| Electric Delta Connection | 380V/50Hz | |

| Motor RPM | rpm | 1450 |

| Mixer Arms | Qty | 3 |

| Scraper Arms | Qty | 2 |

| Hydraulic System Motor Power | kW | 1.5 |

| Mixer Arm RPM | rpm | 24 – 63 |

| Weight | kg | 2500 |

FOR MORE INFORMATION ABOUT OUR PRODUCTS

You can call +90 312 394 19 90immediately. If you want to reach us by e-mail, you can send an e-mail to info@aggmach.com or fill out the request form.

For our newsletters

Sign up